Making infrastructure observable, measurable, and controllable

We design, build, install, and maintain end-to-end monitoring systems for industrial and commercial operational environments.

Energy Monitoring

Understand exactly where energy is generated, distributed, and consumed.

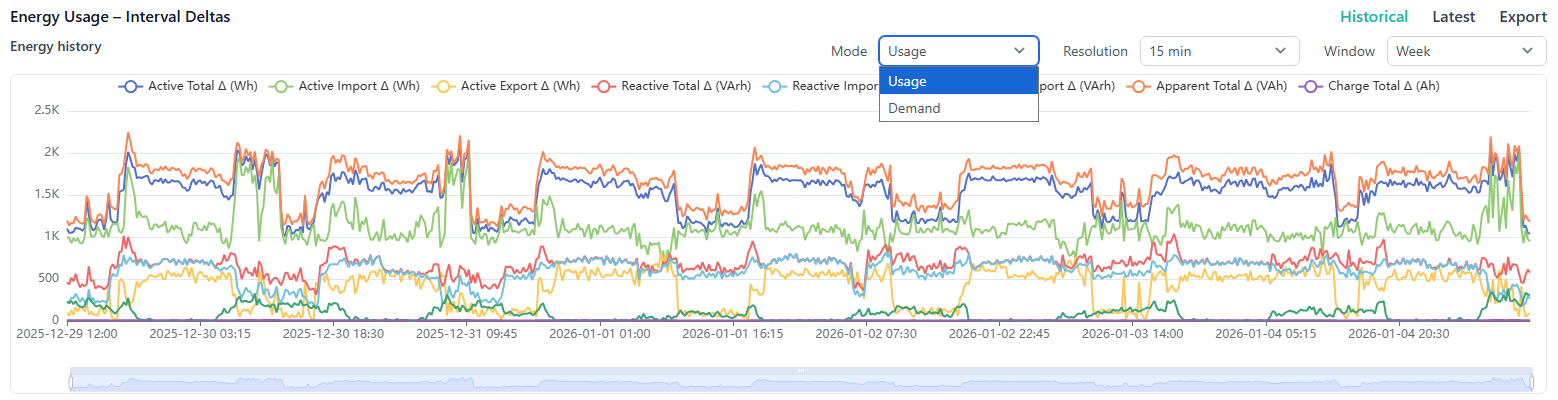

OKLO’s energy monitoring system combines high-resolution, calibrated measurements with a long-term auditable record. This enables real-time operational visibility, recent-history context, and retrospective analysis for both equipment health and electricity cost optimisation.

Operational awareness

Continuous visibility into how facilities and equipment are operating, using live data and recent history to detect abnormal behaviour early.

Cost and demand insight

Clear identification of demand drivers, inefficient loads, and operating patterns that directly influence electricity costs.

Auditable energy records

A verifiable, long-term energy record suitable for billing review, internal reporting, and compliance requirements.

Scalable oversight

A single system for monitoring multiple facilities, sources, and loads with controlled access across teams and roles.

- Phase coverage:

- Single-phase and three-phase monitoring.

- Current range:

- Up to 10 kA per phase using non-invasive sensing.

- Meter depth:

- Up to 72 variables per energy meter.

- Billing analytics:

- Demand tracking and auditable long-term storage.

- Live insight:

- Live readings with recent history for immediate diagnosis.

- Decision support:

- Identify faults and optimisation opportunities.

- Sources:

- Grid, inverter, and generator power monitored independently.

- Loads:

- Energy assigned to sectors, processes, or specific equipment.

- Access:

- Organisations span multiple facilities with role-based visibility.

Interval-based energy deltas and multi-parameter time-series data generated from a deployed system.

Water Monitoring (coming soon)

Water monitoring and control integrated with energy data to build a unified digital view of facility operations.

Oklo Device and Platform

The Oklo system is built as a single, integrated architecture that combines purpose-built industrial controllers with cloud software into a unified operational platform. Hardware, firmware, and backend services are designed together to ensure reliable data acquisition, secure communication, and consistent behaviour from the physical asset through to the dashboard.

Oklo IoT Controller

- • Designed from the ground up for industrial and commercial environments

- • Zero-touch deployment with built-in LTE connectivity and no on-site network configuration

- • Continuous device health monitoring with remote firmware and driver updates managed by Oklo

- • Interfaces with a wide range of industrial sensor and meter protocols

- • Supports control of contactors, relays, solenoids, and other actuators via local or dashboard commands

Data and Control Platform

- • Secure device-to-cloud communication with authenticated devices and encrypted transport

- • Centralised fleet management with continuous device status and health visibility

- • Time-series data storage with validation, processing, and quality controls

- • Dashboards, alerts, and reporting built on a single, consistent data model

- • APIs and integrations for exporting data into external systems and workflows

About Us

OKLO is a design-led engineering company focused on building long-running industrial monitoring and control systems.

Systems are designed end-to-end, without reliance on third-party platforms, allowing behaviour, performance, and evolution to be shaped directly by operational needs.

Design approach

- • Continuous design informed by operational use

- • End-to-end ownership of system behaviour

- • Incremental refinement without platform constraints

Platform principles

- • No dependence on third-party platforms

- • Hardware, firmware, and backend designed together

- • Consistent behaviour from device to dashboard

Operating contexts

- • Monitoring & control delivered as a managed system

- • Embedded capability inside third-party equipment

- • Same platform, different deployment relationships

Contact

- contact@oklo.co.za

- Johannesburg, South Africa